Automatic Roll Air Filters for Paint Booths and Coating Lines ― Ensuring Surface Quality and Clean Airflow

Maintaining clean, consistent airflow is critical to achieving flawless paint finishes in industrial paint booths and automotive coating lines. Dust, overspray, and airborne particles can easily contaminate freshly painted surfaces, leading to visible defects, rework, and costly downtime. Across the United States, Canada, and international manufacturing facilities, the HICLOVER Automatic Roll Air Filter has become a trusted solution for paint booth air filtration and coating line air quality control, offering smart automation, low maintenance, and exceptional filtration consistency.

Precision Air Filtration for Paint Booth Applications

In modern automotive, aerospace, and equipment coating facilities, maintaining a dust-free environment is essential. Even microscopic airborne contaminants can cause blemishes or roughness in paint finishes. Traditional static filters clog quickly under heavy overspray conditions, increasing airflow resistance and reducing booth efficiency.

The HICLOVER Automatic Roll Air Filter solves this problem with a self-advancing filter media system controlled by a PLC-based automation module. As dust and paint particles accumulate, the system automatically advances the media roll, continuously exposing a clean filtration surface.

Key performance features:

-

Continuous self-cleaning and self-advancing media system to prevent clogging.

-

PLC-controlled automation for constant airflow and balanced booth pressure.

-

Compatible with MERV 8C13 media for fine particulate and overspray capture.

-

Reduces manual filter changes, improving operational uptime.

-

Supports compliance with EPA and OSHA air quality regulations.

More details available at www.cloverfilter.com.

Protecting Paint Quality and Reducing Downtime

Paint and coating facilities are among the most demanding industrial environments for air filtration. Unfiltered air can introduce dust, fibers, and even micro-particles of rust or oil, resulting in:

-

Surface defects such as pinholes, craters, or fisheyes.

-

Increased rework and polishing time.

-

Uneven coating thickness due to poor airflow balance.

-

Reduced equipment life from overspray buildup on fans and ducts.

By maintaining a steady, clean airflow, the Automatic Roll Air Filter helps protect paint quality and extend the service life of downstream filtration systems. The result is higher productivity, reduced operational cost, and superior coating consistency―crucial for industries focused on finish quality such as automotive, furniture, machinery, and aerospace manufacturing.

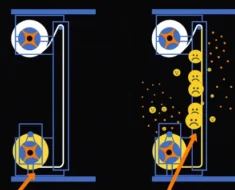

How the Automatic Roll Air Filter Works

The HICLOVER system uses a motor-driven roll media mechanism with a differential pressure sensor linked to a PLC control panel. As filter resistance increases, the media automatically advances to expose a fresh, clean section, ensuring continuous performance.

Technical highlights:

-

Automatic media advancement triggered by pressure differentials or timer settings.

-

Consistent airflow for balanced pressurization inside paint booths and spray rooms.

-

Modular design available in both horizontal and vertical configurations.

-

Corrosion-resistant housing for solvent-rich or humid environments.

-

Energy-efficient design to reduce fan load and power consumption.

This automation eliminates the need for manual filter changes during production shifts, a major advantage for 24/7 paint lines operating under tight production schedules.

Common Applications Across North America and Beyond

HICLOVER’s Automatic Roll Air Filters are widely used in:

-

Automotive paint booths and body shops for primer, base, and topcoat stages.

-

Aerospace component coating lines for fuselage, turbine, and landing gear painting.

-

Industrial equipment and machinery finishing booths.

-

Furniture and cabinetry production lines for clear coat and lacquer spraying.

-

Rail, bus, and truck manufacturing plants with large-scale painting enclosures.

These systems are designed to handle varying overspray loads and dust densities found in both North American and global industrial environments, ensuring reliability under high-throughput operations.

Reduced Maintenance, Increased Efficiency

Unlike conventional panel or bag filters that require frequent manual replacement, the Automatic Roll Air Filter from HICLOVER offers fully automated operation with minimal maintenance. The continuous roll media system ensures a constant filtration surface, reducing downtime and maintenance costs.

Advantages for operators:

-

No production interruptions for filter changes.

-

Lower labor costs and safer operation.

-

Optimized airflow and stable booth temperature control.

-

Easy media replacement using standard roll cartridges.

Designed for Performance and Compliance

Built according to ASHRAE 52.2, ISO 9001:2015, and CE manufacturing standards, the HICLOVER Automatic Roll Air Filter provides reliable and efficient filtration for paint booth ventilation systems worldwide. Each unit can be customized for local codes and facility requirements, ensuring compatibility with HVAC systems, downdraft booths, or crossdraft paint lines.

The HICLOVER Advantage

HICLOVER stands out as a professional manufacturer of automatic filtration systems designed for heavy-duty, high-efficiency air management in coating environments.

Benefits at a glance:

-

Continuous automatic operation via smart PLC control.

-

High MERV efficiency media for precise particulate removal.

-

Customizable structure for new or retrofit installations.

-

Long operational lifespan and reduced total ownership cost.

By integrating a HICLOVER Automatic Roll Air Filter into your paint booth or coating line, your facility achieves consistent airflow, cleaner finishes, and lower maintenance―all while meeting environmental compliance standards.

For full technical specifications or distributor inquiries, visit www.cloverfilter.com.

Contact Information

Mobile (WhatsApp): +86-13813931455

Website: www.cloverfilter.com

Email: cloverfilter@gmail.com

2025-11-01/13:54:54