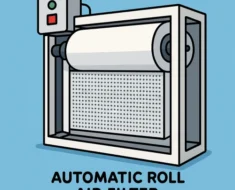

Automatic Roll Air Filters for Compressor Room Intake Systems ― Intelligent Filtration to Prevent Dust and Oil Mist Contamination

Industrial air compressors are the heart of countless production systems, powering pneumatic tools, process lines, and automation networks. However, compressor performance heavily depends on the quality of intake air. Dust, oil mist, and airborne particles can significantly reduce compressor efficiency, increase wear, and contaminate downstream air systems. The HICLOVER Automatic Roll Air Filter provides a high-efficiency, automated solution for compressor room air intake filtration, designed to keep compressors running clean, cool, and energy-efficient across diverse industrial settings in North America and around the world.

Advanced Air Intake Protection for Compressor Systems

In compressor rooms, unfiltered air can cause premature wear to pistons, valves, and bearings, while also fouling coolers and heat exchangers. The result is higher energy consumption, increased maintenance costs, and reduced system reliability.

The HICLOVER Automatic Roll Air Filter overcomes these challenges with a self-renewing filtration system that continuously replaces dirty filter media with fresh material, keeping the airflow clean and stable. Unlike fixed filters that require frequent manual changes, this automated design ensures uninterrupted protection and consistent MERV-rated filtration performance.

Key features and advantages:

-

Automatic filter media advancement controlled by a smart PLC system.

-

Captures dust, oil mist, and airborne contaminants before they enter the compressor.

-

Maintains steady airflow and prevents pressure loss in intake ducts.

-

Significantly reduces manual maintenance frequency.

-

Compatible with horizontal and vertical installation for various room layouts.

Learn more at www.cloverfilter.com/industrial-air-filtration.

Why Compressor Intake Filtration Is Critical

Air compressors in industrial environments such as automotive plants, food processing facilities, mining operations, and energy plants constantly draw in large volumes of air. Even small amounts of airborne contamination can create major operational issues:

-

Dust accumulation increases friction and raises motor temperature.

-

Oil mist or vapor can cause sticky deposits on internal components.

-

Polluted intake air leads to higher pressure drops and reduced flow efficiency.

-

Unfiltered particles accelerate corrosion and mechanical fatigue.

A properly engineered Automatic Roll Air Filter prevents these problems by continuously supplying clean, filtered air to the compressor, extending system life and maintaining energy efficiency.

How the Automatic Roll Air Filter Works

The HICLOVER Automatic Roll Air Filter integrates advanced automation and durable mechanical design. A differential pressure sensor monitors airflow resistance across the filter media. When resistance exceeds a preset threshold, the system’s motor-driven roll mechanism automatically advances a clean section of filter material ― without interrupting airflow.

Technical highlights:

-

PLC-controlled automation for continuous monitoring and precise media advancement.

-

MERV 8C13 rated media suitable for coarse and fine dust filtration.

-

Low-noise motor drive for compressor room environments.

-

Energy-efficient operation maintaining steady airflow and low fan load.

-

Optional activated carbon layers for oil vapor adsorption in humid or oily atmospheres.

The result is a self-sustaining filtration system that eliminates the need for routine manual filter changes ― ideal for facilities where downtime is costly and continuous operation is critical.

More product details: www.cloverfilter.com/automatic-roll-filter.

Applications Across North America and Global Industry

HICLOVER’s Automatic Roll Air Filters are installed in a wide range of industries requiring clean intake air for compressors and ventilation systems, including:

-

Manufacturing plants with high particulate or oil mist levels.

-

Mining and energy facilities operating in dusty outdoor environments.

-

Food and beverage processing where clean, oil-free compressed air is vital.

-

Automotive assembly and paint lines needing precise air balance.

-

Pharmaceutical and electronics facilities with cleanroom requirements.

Whether serving a single large compressor or a centralized compressed air plant, the system’s modular configuration ensures consistent air quality under any environmental conditions.

Energy Efficiency and Cost Reduction

In compressor systems, every 1% increase in pressure drop can translate into measurable energy loss. Static filters often clog quickly, forcing compressors to work harder and consume more power.

The HICLOVER Automatic Roll Air Filter maintains stable pressure differentials, optimizing airflow and reducing energy costs. Its automated filter media renewal ensures that the filter operates within its optimal range at all times, lowering total operational costs.

Operational advantages:

-

Reduces energy consumption by keeping airflow resistance low.

-

Extends compressor lifespan by preventing internal contamination.

-

Minimizes maintenance downtime with automated filter advancement.

-

Provides a cleaner working environment around compressor stations.

See additional insights at www.cloverfilter.com/compressor-room-filtration.

Built for Durability and Compliance

All HICLOVER Automatic Roll Air Filters are manufactured under ISO 9001:2015 and CE certification standards, ensuring reliability and long service life. Units can be customized with stainless steel housings, explosion-proof motors, or corrosion-resistant coatings for harsh environments.

The system is compatible with ASHRAE 52.2 and EN 779 standards for industrial air filtration, meeting air quality and efficiency requirements in facilities across North America, Europe, the Middle East, and Asia-Pacific.

The HICLOVER Advantage

With decades of experience in industrial air purification, HICLOVER delivers robust and intelligent filtration systems that combine automation, efficiency, and longevity.

Why choose HICLOVER:

-

Proven automatic roll filter technology with global industrial references.

-

Smart PLC automation that adjusts to environmental conditions.

-

Custom configurations for compressor intake systems of all capacities.

-

Lower maintenance and superior reliability for 24/7 operations.

-

Full technical support and international logistics coverage.

By integrating a HICLOVER Automatic Roll Air Filter into your compressor room intake system, you achieve cleaner air, longer equipment life, and measurable operational savings ― all backed by precision automation and industrial-grade design.

For detailed specifications or system integration support, visit www.cloverfilter.com.

Contact Information

Mobile (WhatsApp): +86-13813931455

Website: www.cloverfilter.com

Email: cloverfilter@gmail.com

2025-11-02/22:47:24